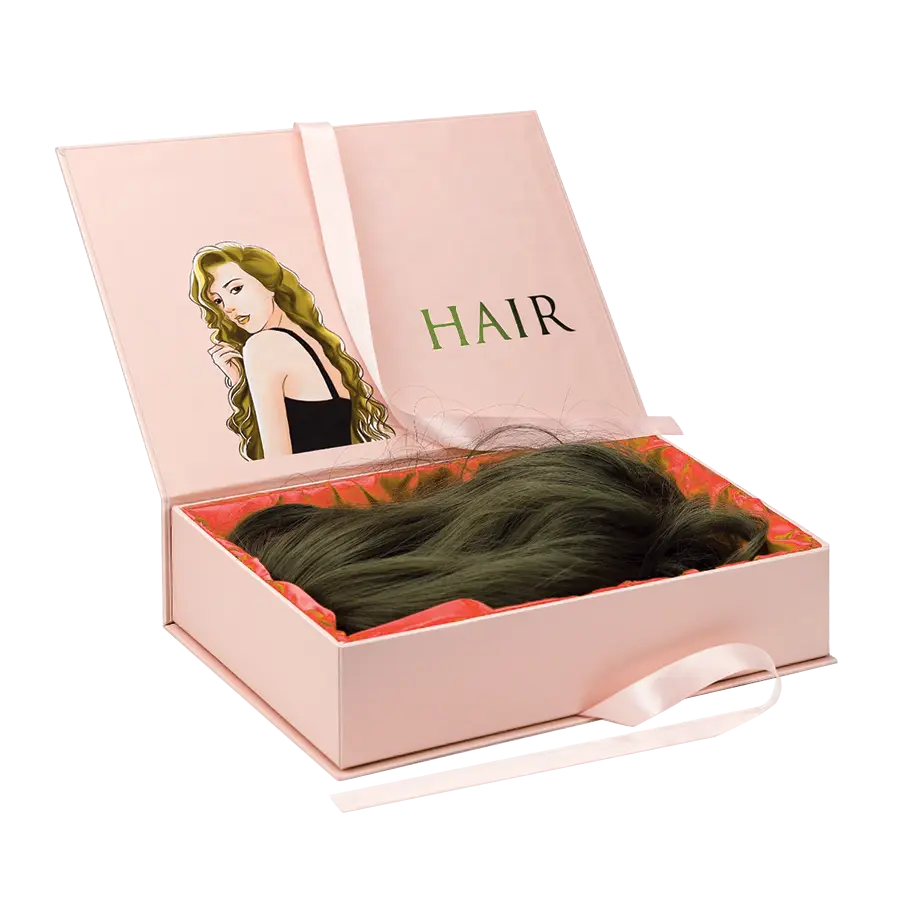

Your search for exceptional and sturdy lip gloss packaging boxes ends with Packaging Bee. We can craft lip gloss boxes in custom shapes and sizes while catering to any specific requirements that you might have. Furthermore, we can help you transform your lip gloss boxes into marketing tools for your brands.

Packaging Bee offers different customizations, such as enticing add-ons and alluring finishing coats. In addition, we also offer the latest printing techniques, colour models, and a variety of packaging materials. If you're looking for a one-stop solution to all of your packaging concerns, then Packaging Bee is the right company for you. So give us a call today, and let's get started!