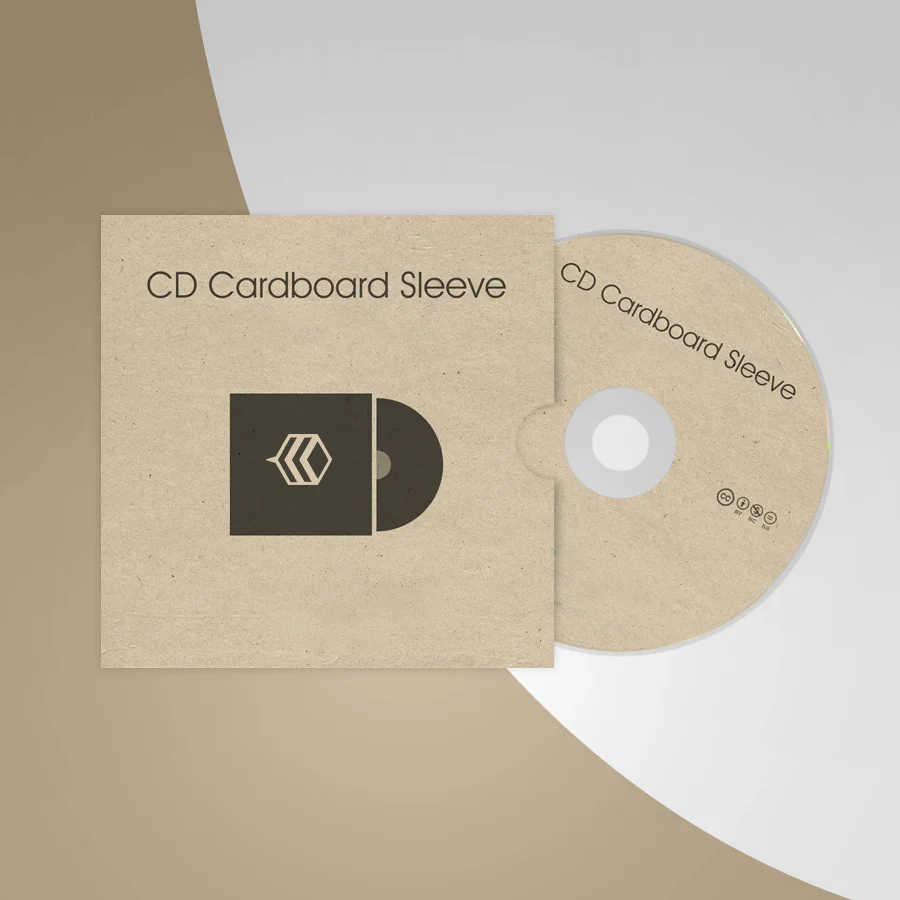

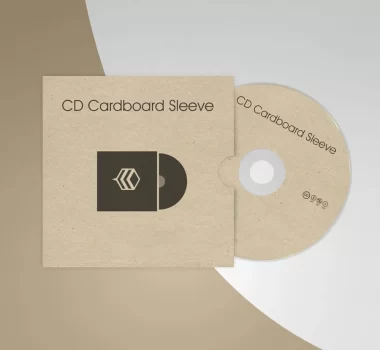

Our CD sleeves are stylish and functional in protecting and storing your discs. We construct your paper sleeve CD from high-quality materials. These sleeves guarantee reliable and long-lasting protection against dust, scratches, and other possible harms. Due to the clear design, it is easy to place a label on the sleeve CD. It helps owners find their CDs easily. Our cardboard sleeve CD is available in multiple sizes. Therefore, they are perfect for people, company advertisements, or merchandising purposes.

Additionally, these are lightweight and portable for easy storage and transportation. We provide a wide range of branding choices for CD sleeve printing. Hence, make it fine and stylish to align with your marketing approaches. The excellent materials of these sleeves protect your CDs from damage. Also, our affordable sleeves add professional style. Order now!