Win Your Market With Sleeve Packaging

When a product is packaged in a box sleeve packaging, it is enclosed in a thin layer of substance (often paper, cardboard, or plastic film). It is open on both sides. When finished, the sleeve is usually sealed or attached at both ends. Thus, to create ensconced and reliable packaging.

Wrapping bottles, cans, or boxes with custom paper sleeves can help spread brand awareness. Also, it offer more details about the contents. You can also use it for promotional offers. Such as free samples or gifts with purchase, or for multipacks. Where many goods are grouped together.

Packaging in sleeves is widely popular for many different types of consumer items. It includes food and drink, cosmetics, and homewares. High-quality graphics and printing allow for easy personalisation. Eventually making it ideal for promoting a product's brand and visual identity. Sleeve packaging is eco-friendly in addition to being convenient to use and discard.

Increased Demand for Personalised Paper Sleeve Packaging

Every brand wants to set themselves apart from the competition. Thus, to establish a name in product packaging. Therefore, a growing number of companies are opting for custom sleeves for boxes for their products. Some of the following explains the growing popularity of bespoke sleeve packaging:

Packaging Sleeve Printing Ensure Success in Branding:

With custom sleeve boxes, companies can present their brand in a polished and impeccable manner. High-quality graphics, logos, and other branding components help businesses stand out in Competitive environment. Also, to leave a lasting impression on customers.

Adaptability:

The adaptability of carton sleeve packaging makes it a viable choice for companies of varying sizes and specialisations. diy packaging sleeve can accommodate a wide variety of products. You can use them from food and drink to cosmetics and electronics.

Tamper-Evident:

Products like medications and perishable foods frequently need tamper-evident seals. Hence custom packaging sleeves are widely employed for these types of products. You can have faith in our quality and security of a product packaged in a bespoke sleeve. The reason we will include a tamper-evident seal.

Environmentally Friendly Packaging:

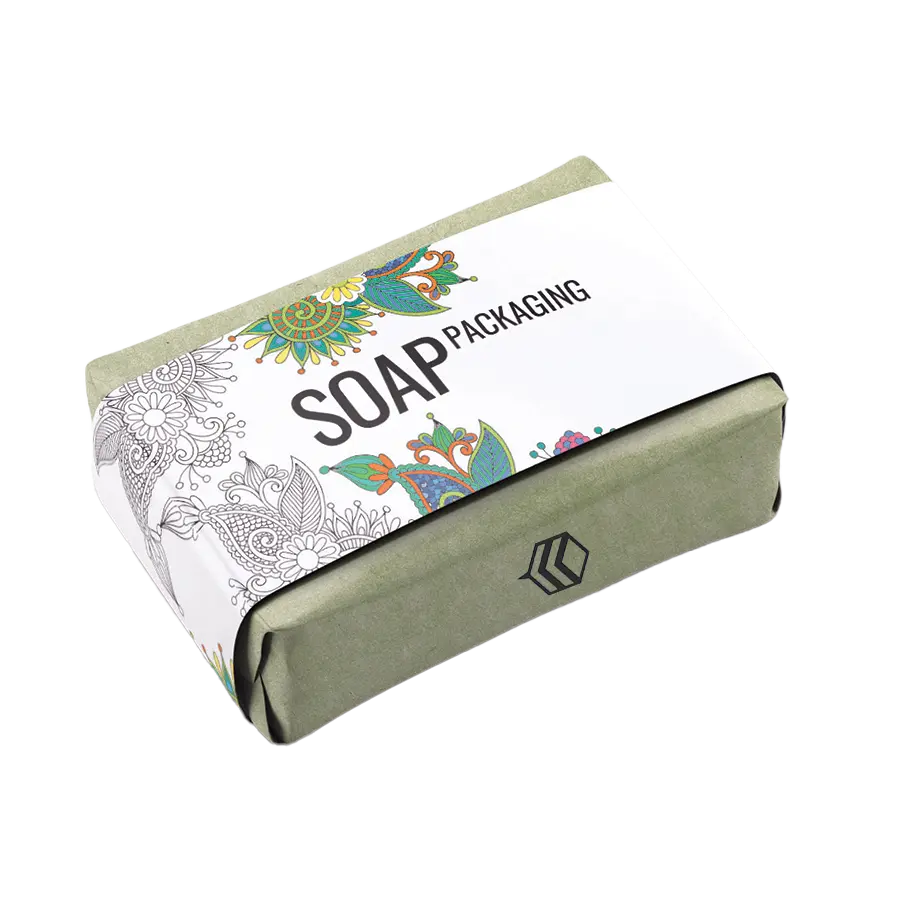

It is sustainable and appealing to eco-conscious consumers. We also Kraft custom soap sleeve packaging from eco-friendly materials like recycled paper or biodegradable polymers.

Therefore, bespoke box sleeve packaging is on the upswing. As it allows companies to differentiate themselves from competitors. Moreover, improve product appeal without breaking the bank.

Making Custom Packaging Sleeves More Interesting

Businesses may increase the allure of sleeve boxes by giving customers a one-of-a-kind packaging experience. One way to do this is to include things like eye-catching visuals. Moreover, use premium materials, and interactive components in the design of the product. Another way to make the goods stand out and leave a lasting impression is to add a personal touch. design a unique unpacking experience. We offer all of these with our sleeve packaging.

With these methods, companies may design sleeve for packaging. that not only sells more of their product. However, it also strengthens their brand's reputation.

Here are some things to think about if you want your paper sleeve packaging to be interesting and stand out from the crowd:

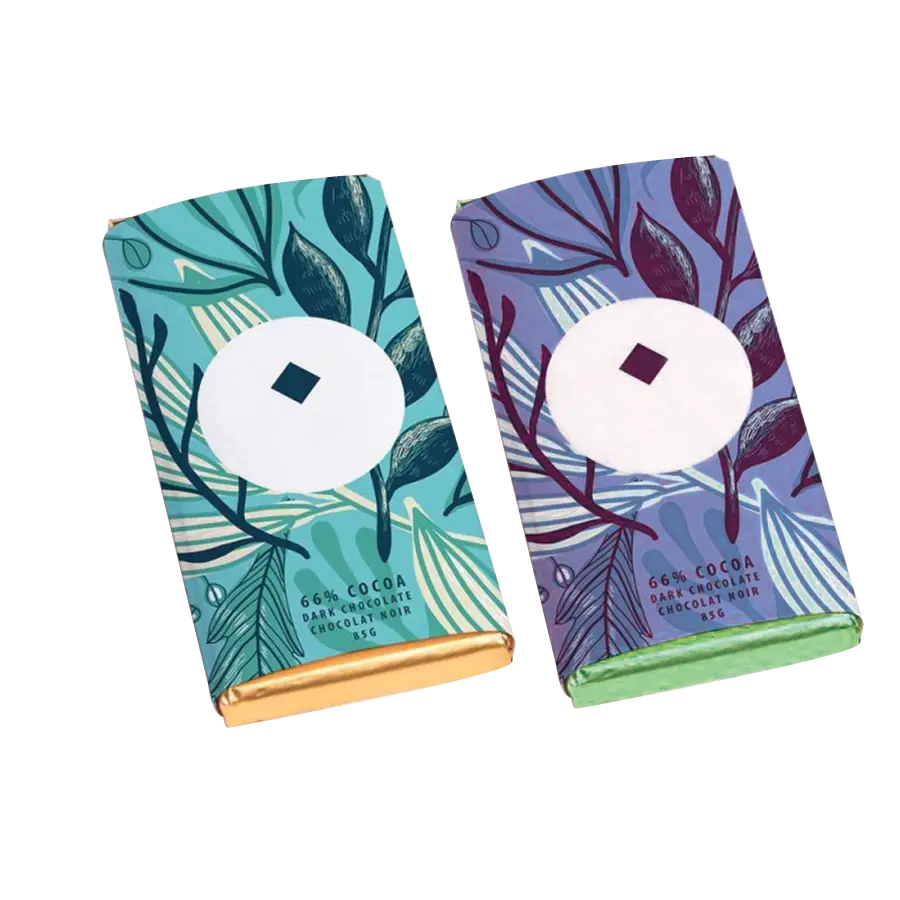

Catchy Images on Packaging Sleeve Printing Always Work

Make the sleeve packaging for your product stand out by using high-quality designs and vibrant colours. Features, advantages, and the overall brand message should all be communicated through visuals.

Custom printed packaging sleeves' visual elements, such as artwork and colour scheme, are adaptable to both the item's intended market and its intended usage. Nonetheless, the following are examples of widely used artwork and hues for sleeves:

Bright Colours:

Custom paper sleeves take your advertisements to another level when you use bright colors in your packaging. This is what we do for you while making your selleve packaging. Intriguing colors like red, yellow, and purple on sleeve for packaging may help your goods stand out from the competition.

Pictures of Products:

Customers will be better able to envision the product and its qualities. They can get aid of high-quality photos of the product or the product in use. So, a miniature picture on a diy packaging sleeve can help.

Never Forgo Your Brands Logo

The addition of the brand logo to the sleeve packaging aids in the promotion of brand awareness and brand loyalty. Logo is one technique to get people to remember and love your brand. Just put your logo on the cheap packaging sleeves. A brand's logo is a strong symbol. In addition, it represents the company's identity. Aslo, stands for its core beliefs to the public. Putting the company logo on the package sleeve is a great way to get people to take notice of your business.

Constant Exposure of Brand Logo is Crucial

Customers build familiarity and trust with a brand by constantly being exposed to its logo. Customers are more likely to stick with well-known companies they're already familiar with. Furthermore, a logo's design may evoke a favourable emotional response from clients and set the company apart from the competition. Including the company logo on the carton sleeve packaging is a must. It is a highly effective marketing tactic for companies seeking to increase brand awareness and customer loyalty.

Stimulating Typefaces:

The product's message may be better communicated. Additionally, target audience more easily. Moreover, won over with the use of striking and distinctive typography. The efficacy of a product's message can be greatly affected by the designer's choice of font. We will use eye-catching, one-of-a-kind typography on custom sleeves for boxes. It is a great way to get your product's message out and win over your target demographic. The use of typography has the potential to convey meaning and make an impression on the viewer. You can use typography on custom printed packaging sleeves to target specific demographics. For instance, a youthful audience may respond positively to whimsical, fun fonts. In contrast, an older, more serious crowd could prefer clean, minimalist fonts. In general, using eye-catching, original typography may boost a product's visibility in the marketplace. Also, it facilitate deeper connections with its target demographic.

Designs and Tecture of Sleeve Packaging:

Add visual appeal and a more tactile, and opulent feel to the card packaging sleeves . Our experts will employ patterns and textures such as polka dots, stripes, or embossed textures.

cheap packaging sleeves should ultimately represent the product's branding and messaging. Thus, appeal to the target demographic via the use of appropriate visuals and colours. It's crucial to give thought to the packaging as a whole. It help to make sure it's consistent and conveys the product's worth to the buyer.

Exceptional Components for Custom Paper Packaging Sleeves

You might provide your consumers with a multi-sensory experience by employing unconventional materials like textured or embossed paper. This may add a sense of class and distinction to your goods. We offer amazing sleeve for the following products:

- coffee cup sleeve

- sock packaging sleeve

- food sleeve packaging

- bottle sleeve packaging

- cardboard sleeve packaging

- kraft packaging sleeves

- soap sleeve packaging

Packaging Sleeve Material Considerations

Companies need to think about the product they're packaging. How the packaging will be used. Furthermore, the material's influence on the environment. Consider it when deciding what kind of sleeve packaging to employ. Popular options for sleeve packaging materials include the following:

-

Paper:

Paper is a widespread and eco-friendly material for sleeve packaging because of its adaptability and low environmental impact. Food and drink packaging made from it is much sought after. Since it is convenient to transport, light in weight, recyclable, and simple to print on.

-

Cardboard:

Cardboard is a strong and long-lasting material. You can design and print cardboard packaging sleeves in any way you choose. It is widely employed in the packaging of consumer items including electrical gadgets, cosmetics, and food.

-

Plastic Material

Being a flexible and long-lasting material, plastic is frequently utilised for sleeve packaging. But, businesses should take plastic's environmental impact into account and choose eco-friendly choices like biodegradable or recycled plastic.

-

Green Packaging

Biodegradable materials are more environmentally friendly than their non-biodegradable counterparts, such as cornstarch or mushroom-based packaging. These materials degrade in the environment less quickly than others because they decompose naturally.

When deciding what to use for sleeve packaging. All companies should think about the product within. In addition, how people will use it. Also, how it will affect the environment. The material selection must be economical, practical, and eco-friendly.

Including Dynamic Components in Custom Paper Packaging Sleeves

Making use of QR codes, augmented reality, and scratch-off promos. These are all great ways to add some fun. Also, interactivity to your sleeve packaging. It will keep your consumers interested and involved. Customers are more likely to buy a product with an interactive feature on the sleeve. Only if they enjoy interacting with the package.

Personalisation:

Adding the customer's name to your sleeve packaging is a great way. It shows your appreciation for their business. Including any or all of these factors can have a major impact on revenue. Customers who have the sense that their opinions matter. They are more likely to form a favourable association with the company. Also, stick with it. Also, by making the consumer feel special and unique, personalisation may increase word-of-mouth advertising and word-of-mouth marketing. It is our guarantee that personalised packaging will boost sales. Moreover, assist you in brand awareness, and consumer loyalty. Thus, adding custom touches to sleeve packaging is a great way to boost sales.

Non-Detrimental to the Environment:

Win over clients who are worried about the environment. Switch acout eco-friendly materials and sustainable packaging methods. To attract eco-conscious consumers, it is essential to give thought to using eco-friendly materials and sustainable packaging for product sleeves. Customers are expecting more eco-friendly solutions as the packaging business is responsible for a lot of waste and pollution. Let us switch you to more eco-friendly packaging options like biodegradable paper, recycled paper, and compostable materials. Thus, you can help save the planet.

Improve Eco Friendly Initiatives

Improve the environmental friendliness of packaging by using sustainable packaging practices. These efforts involve limiting waste, and decreasing the carbon footprint of production. Additionally making use of renewable energy sources. Some consumers place a premium on ethical and ecologically responsible business methods Therefore, are more inclined to buy goods that share those values. Businesses may win over these clients. Additionally, can establish a good reputation as ecologically responsible and mindful organizations. Just by adopting sustainable packaging methods. In the long run, both the environment and the bottom line may gain from the use of eco-friendly materials and sustainable packaging.

Protect the earth with every package - choose biodegradable material, make a sustainability a practice

With these methods, you can design sleeve packaging that is not only eye-catching. However, it is also memorable, and interactive. Thus, true to the values and message of your business. Keep in mind that a coherent and effective marketing plan is important. It relies on keeping the packaging design in line with the brand identity. Also, consider product positioning.

Industries Where Sleeve Packaging is Popular

Standard sleeve dimensions shift from one industry to the next and from one product to the next. While sleeve packaging comes in many shapes and sizes, some of the most common ones are:

Beverage Industry

Beverage sleeves typically come in two sizes, 12 ounces, and 16 ounces.

The Cosmetics Business:

The most often used cosmetic sleeve package sizes range in diameter from 1.5 inches to 2.5 inches.

Food Business:

The dimensions of food sleeve packaging are quite variable. The most frequent sizes for takeaway containers are 8 oz, 16 oz, and 32 oz.

The Tech Sector:

The dimensions of technology sleeve packaging can change as needed to accommodate the goods within. Popular dimensions are 5 by 7 inches or 8 by 10 inches.

It is the product's size and form. Moreover, the intended purpose of the packaging is to determine the standard size of sleeve packaging. Moreover, You should take both the product's specifications and the target market's preferences into account. When you are deciding on a sleeve package size.

What Makes Our Sleeve Packaging Excellent?

All of your packaging needs will met by Packaging Bee. We are dedicated to offering only the highest quality services. Even if you need custom sleeve packaging. We have you covered there. Moreover, we are making an impact with cutting-edge methods and years of experience. Our premium sleeves are crafted from long-lasting materials. We guarantee to provide excellent protection for your items while also looking terrific.

Our sleeve packaging is convenient, long-lasting, eco-friendly, and cheap. We offer all these without sacrificing quality in any way. If you choose us as your packaging provider, you'll be making a good long-term decision for your company. Then why hold off? Get in touch with us immediately to talk about your packaging needs. It's time to take advantage of our premium sleeve packaging.