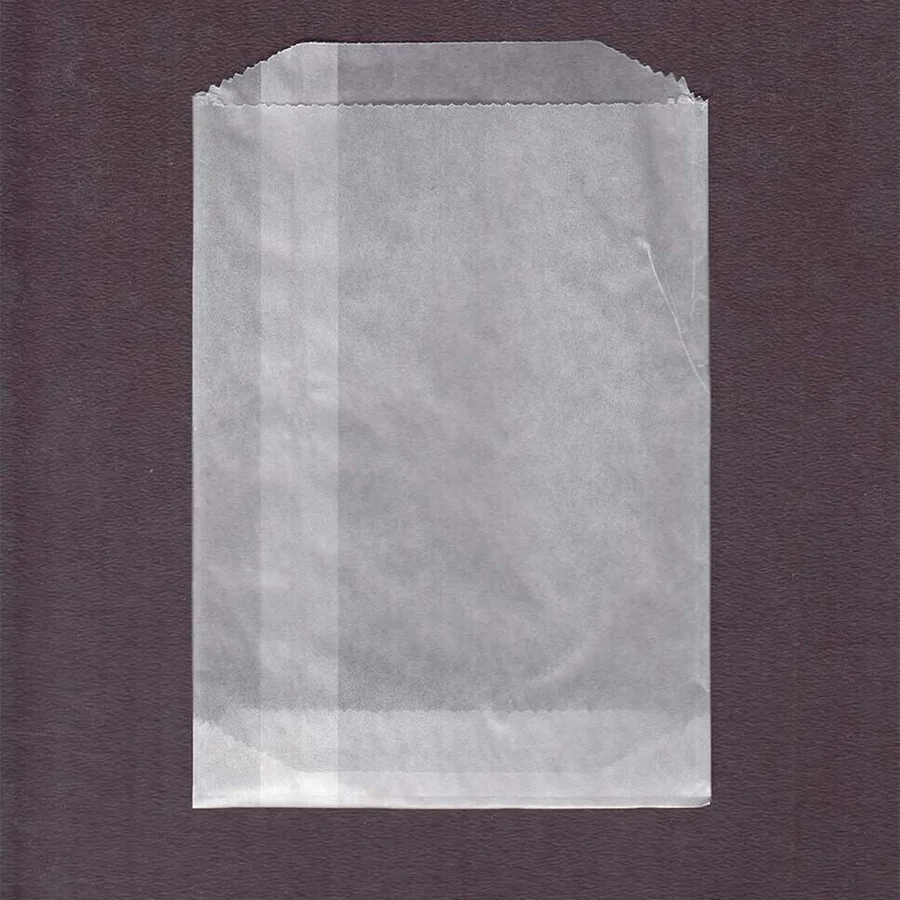

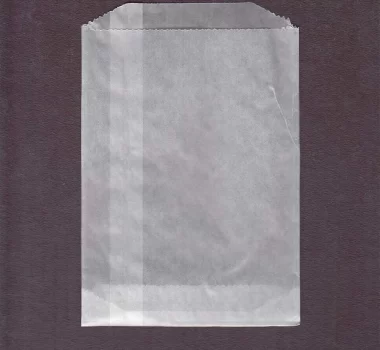

If your company is searching for a way to package its products in a clean and beautiful manner, then look no further than our glassine paper bags. We make them from a smooth, semi-see-through paper that has a modern, simple, and substantial look to any item you put into them. They are naturally resistant to grease, moisture, and air; therefore, they make it easy to protect and keep your food items fresh and delicious.

Since they are acid-free, our bags are safe storage for delicate items such as photographs, art prints, or important papers, and they will guard your products against smudges and handling. In addition, our glassine wax paper bags are completely recyclable and biodegradable, which will impress those customers who care about the environment. So whether you are using them for food like cookies, or other small goods like cards, you will convey quality.