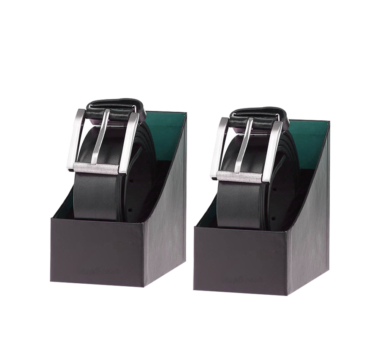

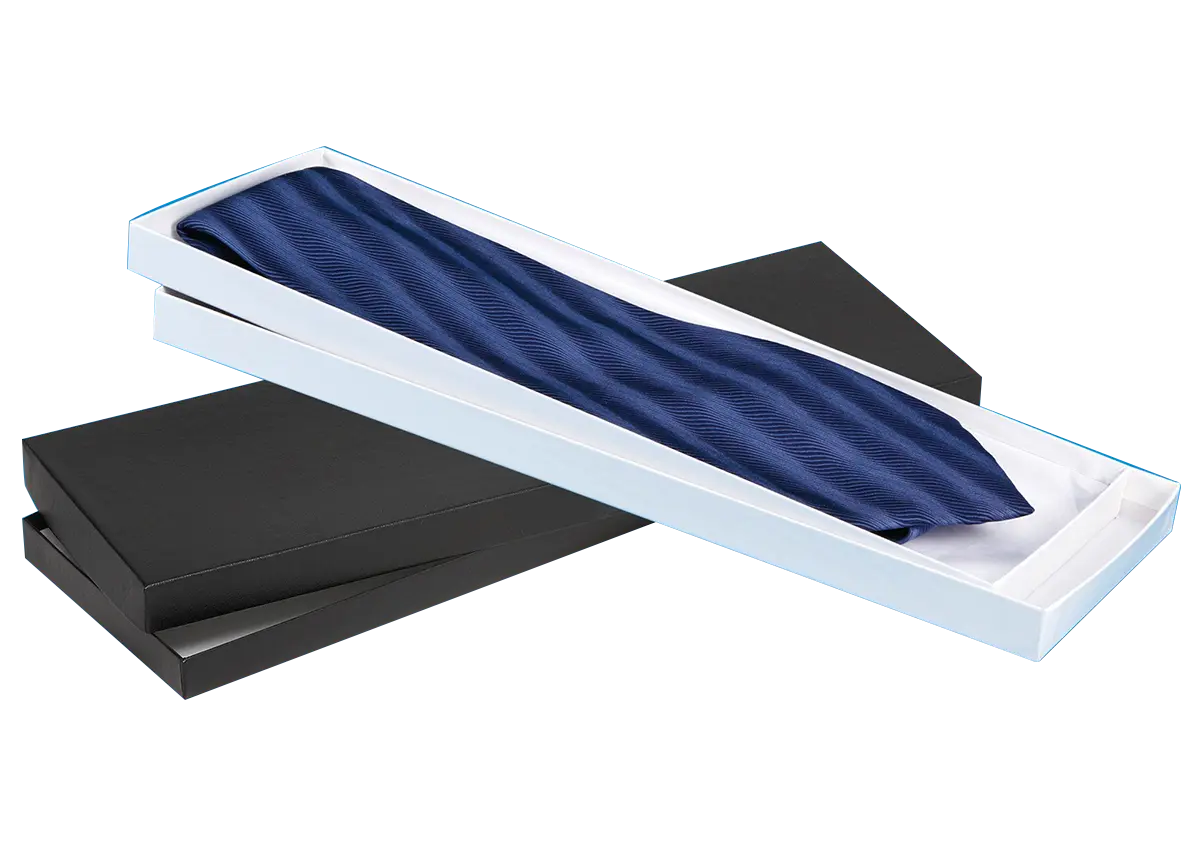

Are you looking for high-quality custom belt boxes that offer a good ROI and can help promote your brand too? If yes, then you can rest easy for you have found Packaging Bee. We offer custom belt and belt buckle boxes at cost-effective prices. In addition, we can also create them in custom shapes and sizes based on your needs.

We offer different packaging materials, printing techniques, and colour models. Furthermore, we also offer different customisations, such as enticing add-ons and attention-grabbing finishing coats. Last but not least, Packaging Bee also offers prototyping options for belt boxes. So, what are you waiting for? Connect with us today, and let's create truly spectacular belt packaging!