26

By: Harry Lee

A beginner-friendly guide on dielines, box dieline design, and custom tuck boxes

Dieline acts as the blueprint in Packaging and printing. But what is a die line? Why does it matter in Packaging? Nice Packaging indeed makes all the difference. Packaging protects the product and gives it a clean appearance. It is also responsible for distinguishing it from others.

One of the key aspects of the design of the Packaging is the dieline. Dieline is a key factor when you’re designing products for the first time.

In this blog, we will explain the basic principles underlying the concept of a dieline. You will learn about its meaning and use and real-life examples also, how it comes in handy when designing custom tuck box-type Packaging or any form of Packaging.

What is a Dieline?

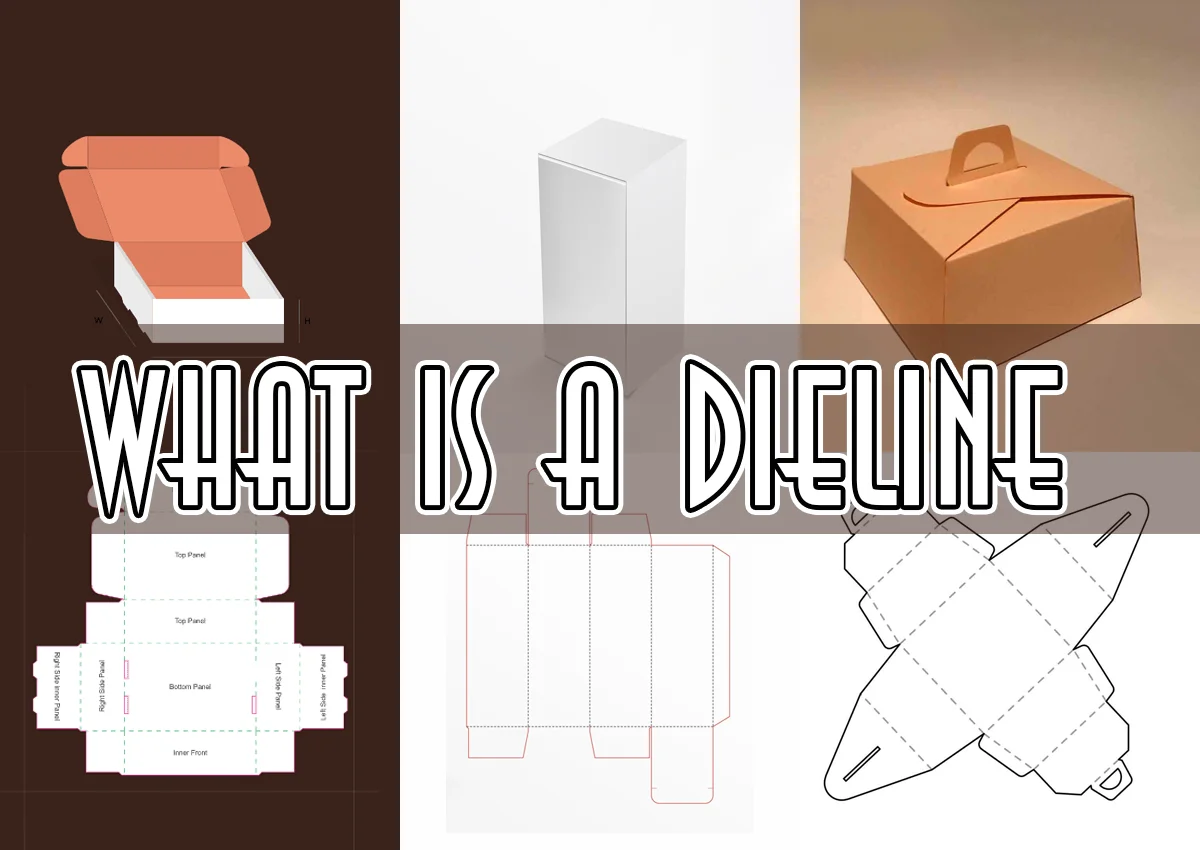

A Dieline refers to a flat outline that indicates where and how the cutting and folding of a box or any type of Packaging will be performed. Think of it as a drawing to convert a flat sheet into a box. The lines show where to cut, fold, and glue.

For a box dieline, the layout shows the shape of a box before it gets folded. This is to ensure that everything fits perfectly. This is an outline that designers use to place the logo, artwork, and text in their correct positions.

So, we can define a dieline as a printout that shows how a screen or Packaging is shaped before its actual production.

What Does a Dieline Do?

This makes your Packaging look neat and professional. Without a proper box pack dieline, a box may not close properly or may cut off the design. Therefore, every packaging design must have a clear dieline before printing. Otherwise, it will compromise the product packaging.

A dieline help:

- Shows where one must cut and fold a material.

- Aligns the design forward so nothing goes out of the centre.

- Prevents some printing and cutting mistakes.

Dieline meaning in Packaging

In Packaging, “dieline” refers to outlines that indicate to printers where to cut and fold the material. These lines will not appear on the final box. They are just part of the design file.

The outlines of the die lines mean that they indicate places on the final package. Its dies would be positioned during the production of the package.

Some dieline examples include customisable cosmetic boxes. You need a die line about the specifics of where the flaps fold and how they assemble. This is for the convenience of the designer and the printer to operate on the right layout.

How to Create a Dieline

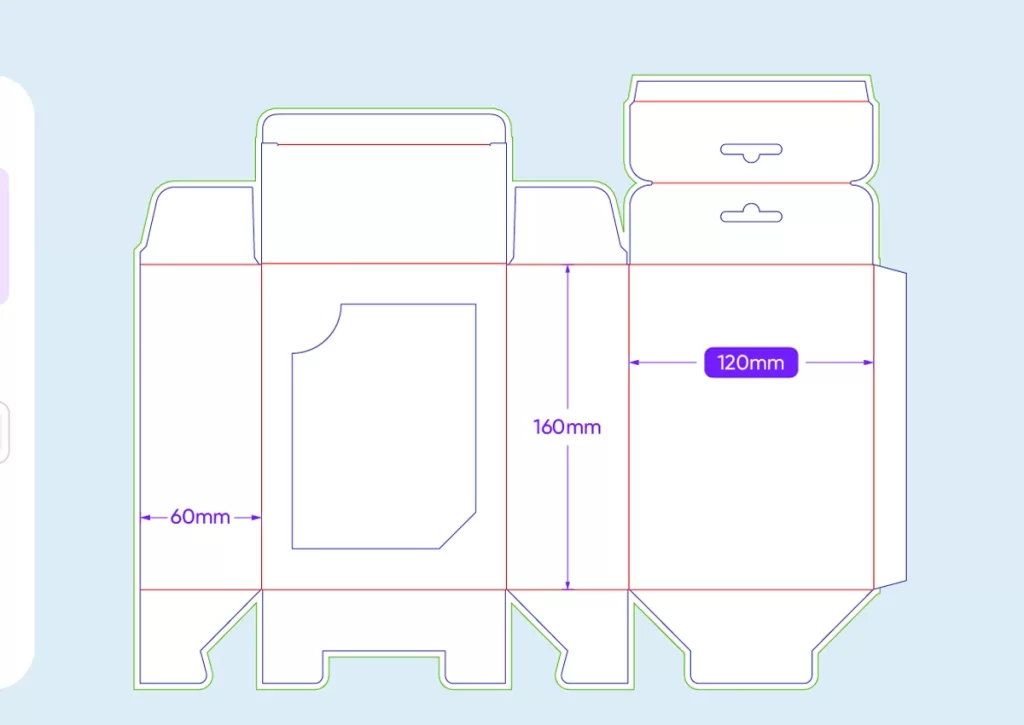

It is a stepwise process for creating a die line, which mostly involves design software such as Adobe Illustrator. Here’s how:

You take your product, knowing the actual measures such as length, width, and height of the item that the Packaging has to hold.

- Sketch your layout. Create a flat version of your box shape (like unfolding it on paper).

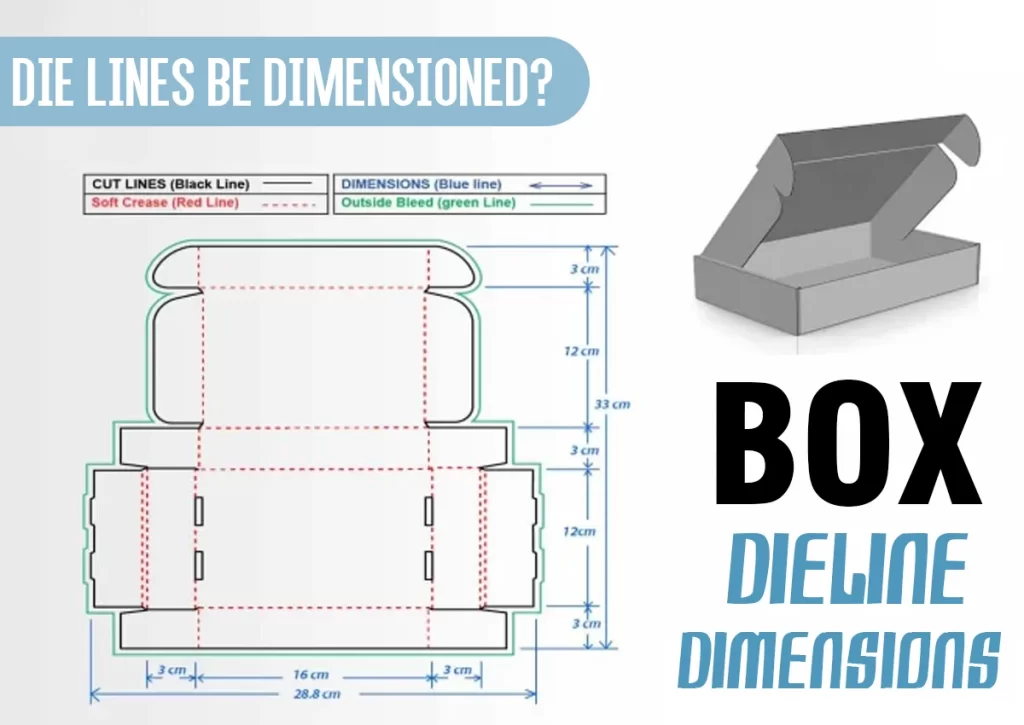

- Even cut and fold lines-another magenta colour for cuts, blue for folds-are drawn.

- Include bleed and safety zones. Bleeds are areas that extend color beyond the trim to avoid pesky white edges.

- Safety margins ensure that text/images aren’t cut. It is vector-based based so that any die line will be scalable at printers without causing loss in quality.

There are many packaging companies (like Packaging Bee UK) that offer die-line templates or design services for them. It is especially for those who cannot do their design.

Dieline Examples

Let’s see some of the most common examples:

Custom tuck boxes

These boxes have small flaps that ‘tuck’ into the sides. The dieline would show where those flaps appear and how they fold in.

Shipping boxes

Mostly made of thick cardboard. The decline would show where the flaps meet and where the tape would be applied.

Retail boxes

These are usually used for beauty products, gadgets, and the like. Dielines like these usually have some kind of window showing the product inside them.

Looking at the dieline examples, you can see how flat shapes become boxes.

Dieline Design Tips

Use clear, straight lines

- Different colours for cuts, folds, and glue areas

- Leave enough space between the text/logo and the edges

- Do not allow folds near important areas

- Print a sample and check it before the final printing

These simple steps will cause less trouble, leaving their Packaging sharp and clean.

Why Dielines Matter for Custom Tuck Boxes

Custom tuck boxes are typically used for small products such as candles, cosmetics, and electronics. They look tidy and open easily. But if there is an issue with the box dieline, it may fold incorrectly, or the design may get hidden in a fold.

So, it is crucial to ensure you have the correct box packaging dieline when designing custom tuck boxes. This is why Packaging Bee UK helps you set up the correct dieline, so your design is displayed perfectly on the final box.

Characteristics of Corrugated Cardboard

Corrugated cardboard is a common material for Packaging due to its strength and flexibility. Some attributes of corrugated cardboard include:

- Strength: It can hold heavy weights, and it protects fragile goods

- Lightweight: Strong but weightless for transport

- Customisable: It can work with so many die-cut designs

- Green: It is made from recycled material and is recyclable

- Shock Absorption: A Stronger, wavy middle layer cushions the product inside.

Using corrugated cardboard and a smart box packaging dieline is a winning combination for shipping and retail.

Final Thoughts

Dielines may not seem very important in the bigger picture of your packaging adventure, but they are a very significant step.

A good, clean, and clear dieline design will ensure that your finished product looks professional, works effectively, and protects your products.

Whether you are designing a box dieline for retail Packaging or creating unique custom tuck boxes, it is worth considering and understanding and investing your time in your dieline.

For professional advice, dieline templates, or if you simply want to create your own unique product package, we are here to deliver your packaging ideas flawlessly at Packaging Bee UK.

FAQ's

-

What are dielines?

Dielines are flat diagrams that show how packaging will be cut and folded before it is printed and assembled. -

What is a dieline in packaging?

In packaging, dielines are a standard layout guide that describes the layout needed to design your packaging and then cut and fold your boxes or product containers. -

How to create a dieline?

Be sure to use design software like Adobe Illustrator or comparable software to lay out your cut lines, fold lines, and bleeds. Also, be sure to add exact dimensions, so the final packaging is correct for the product. -

Should packaging die lines be dimensioned?

Yes, Dielines are the correct dimensions because you want your final packaging to fit your product. -

What is the purpose of a dieline?

Dielines help ensure how you designed your packaging design will be printed, folded, and cut accurately without misalignment or mistakes.