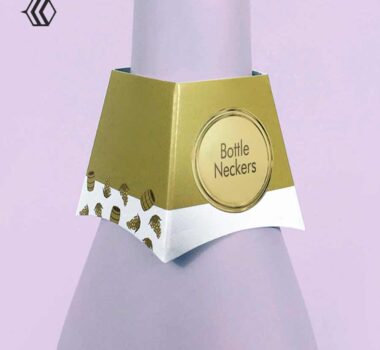

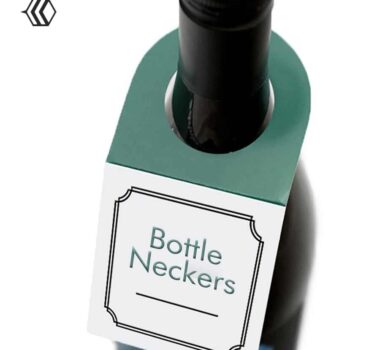

Are you looking to represent and promote your products more effectively on bottles? If so, contact us to learn more about the customised bottle neckers we offer.

We specialise in manufacturing custom-made bottle neckers at competitive prices with fast turnaround times. Our team consists of experienced professionals who are always happy to help with the designing and printing process. We also offer a wide range of finishing coats and add-ons to choose from for your design to give it the perfect finish. So, what are you waiting for? Contact Packaging Bee today to get started on your bottle neckers!