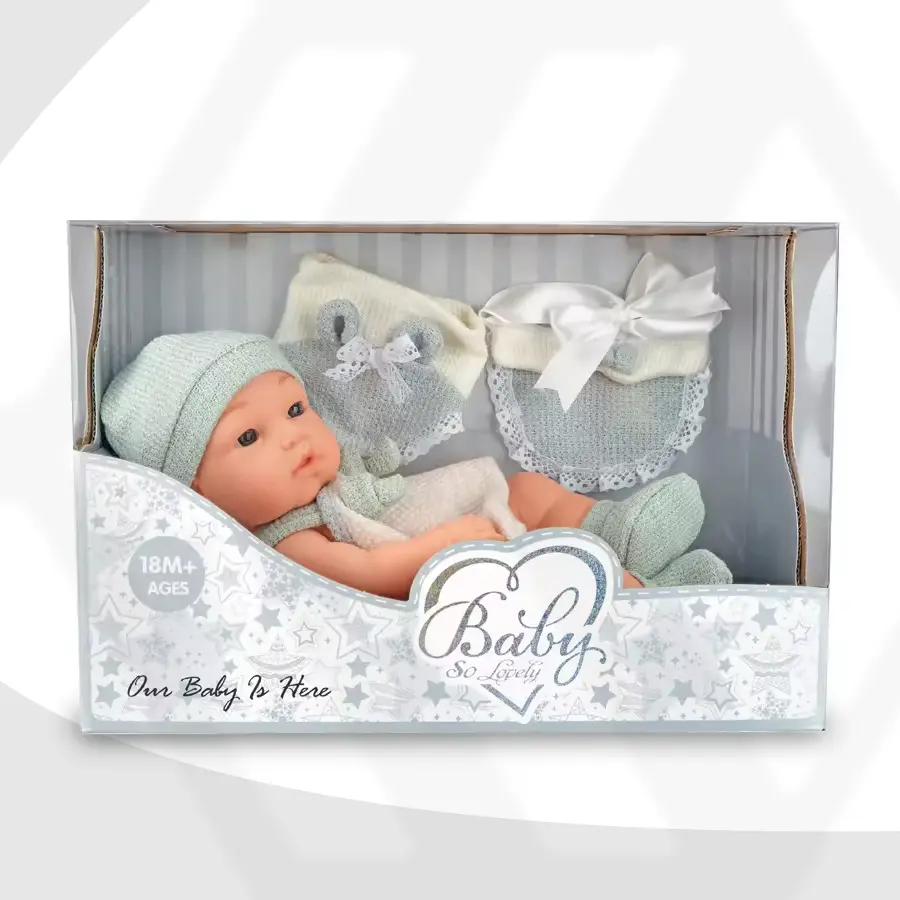

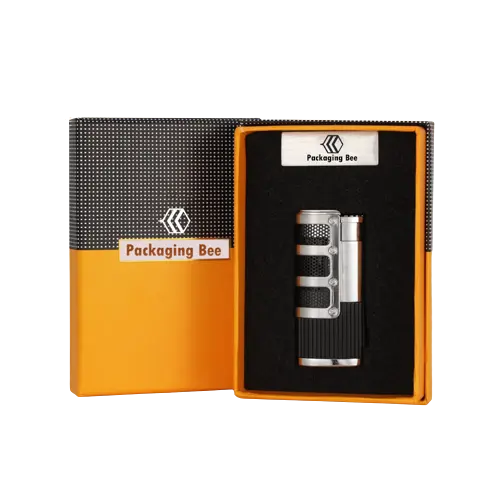

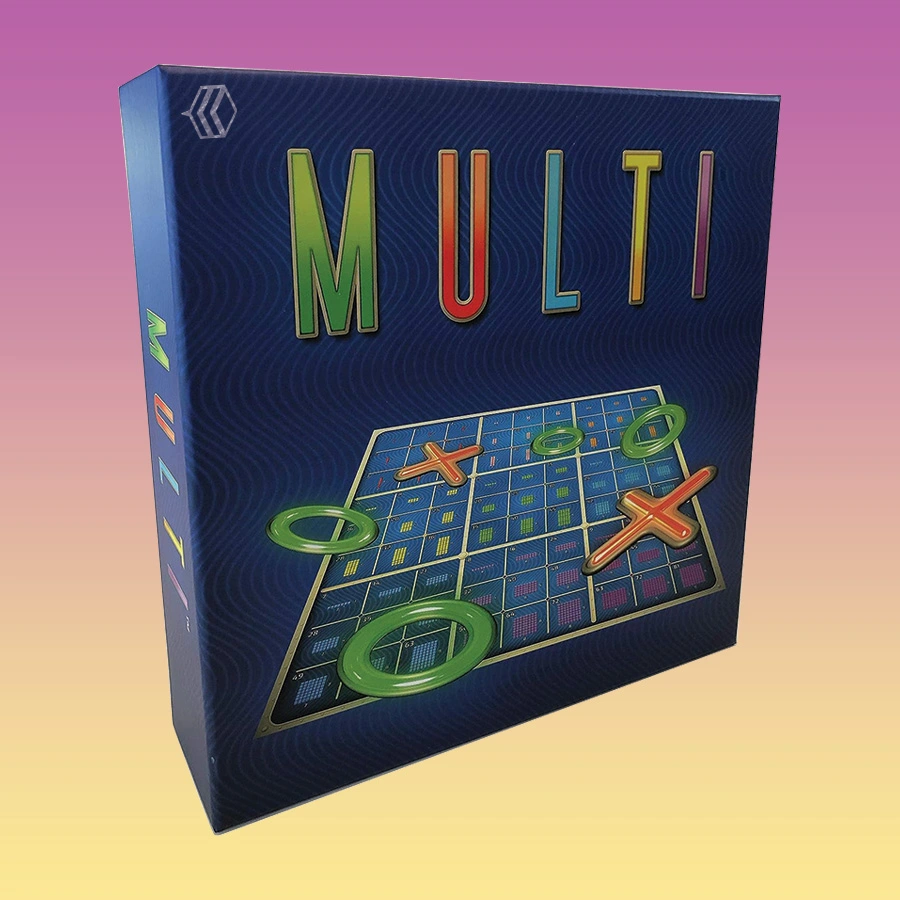

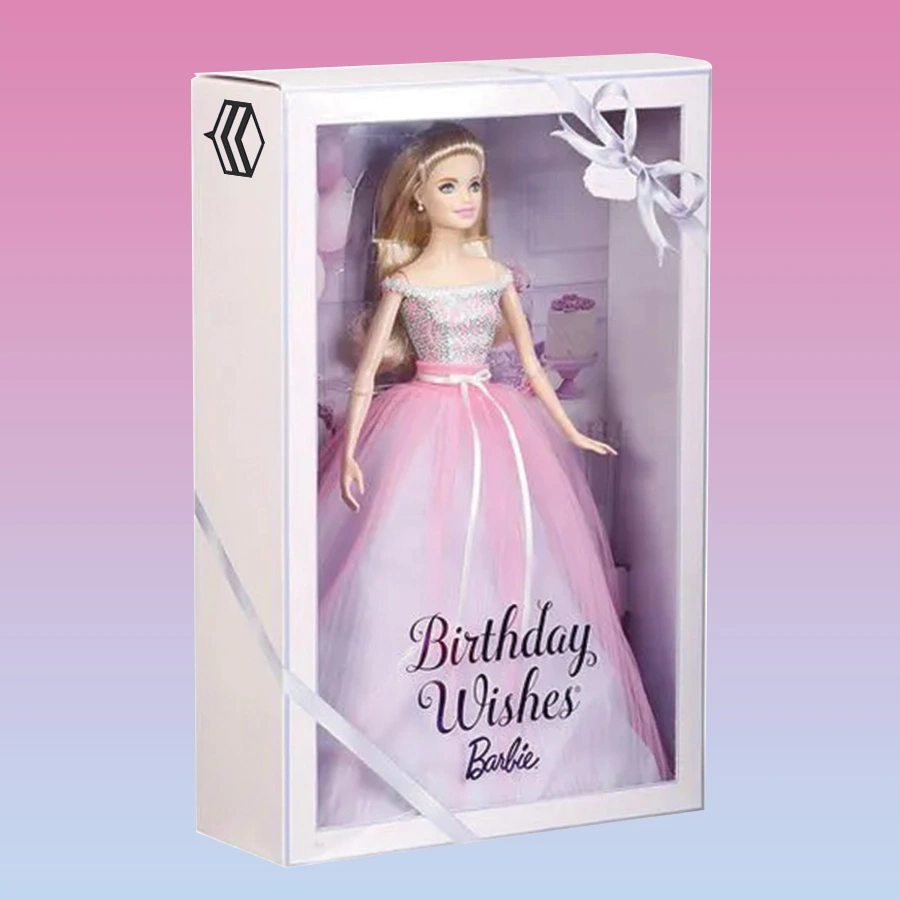

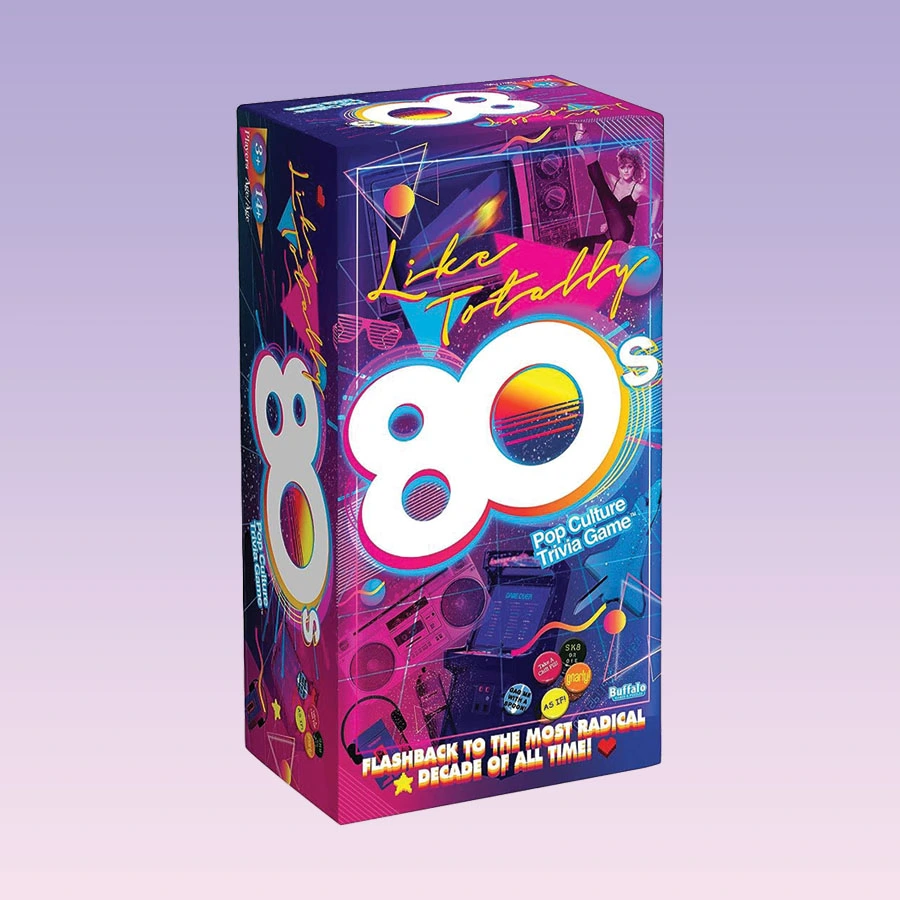

You don't need to settle for cube boxes that are made using low-quality materials, which cannot protect your product adequately. Furthermore, you don't need to waste money on bad printing techniques with a subpar finish. Packaging Bee helps you rise above those problems by giving you the best custom cube boxes in the market.

We use superb packaging materials that offer you various properties to help you make cube boxes that fulfil your particular needs. Our printing techniques and colour models help ensure that your custom cube boxes are transformed into modern masterpieces. Furthermore, we offer various add-ons and finishing coats that help you create something, unlike anything your customers offer.

So get in touch with Packaging Bee and make your packaging dreams come true!