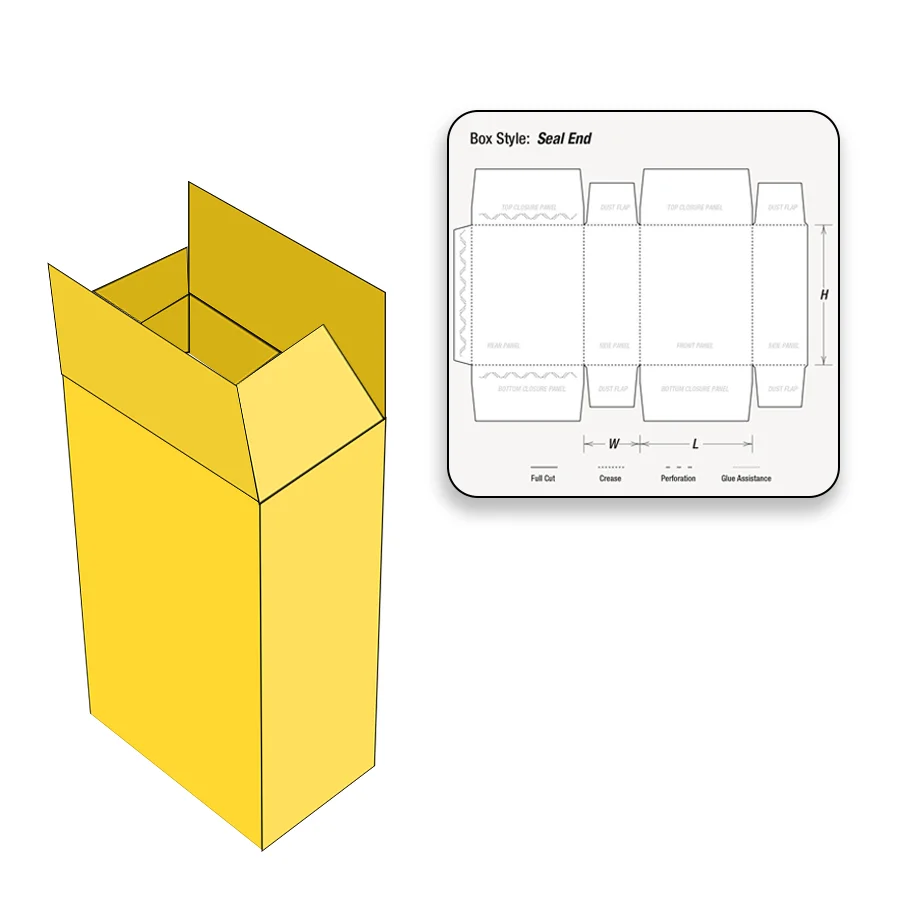

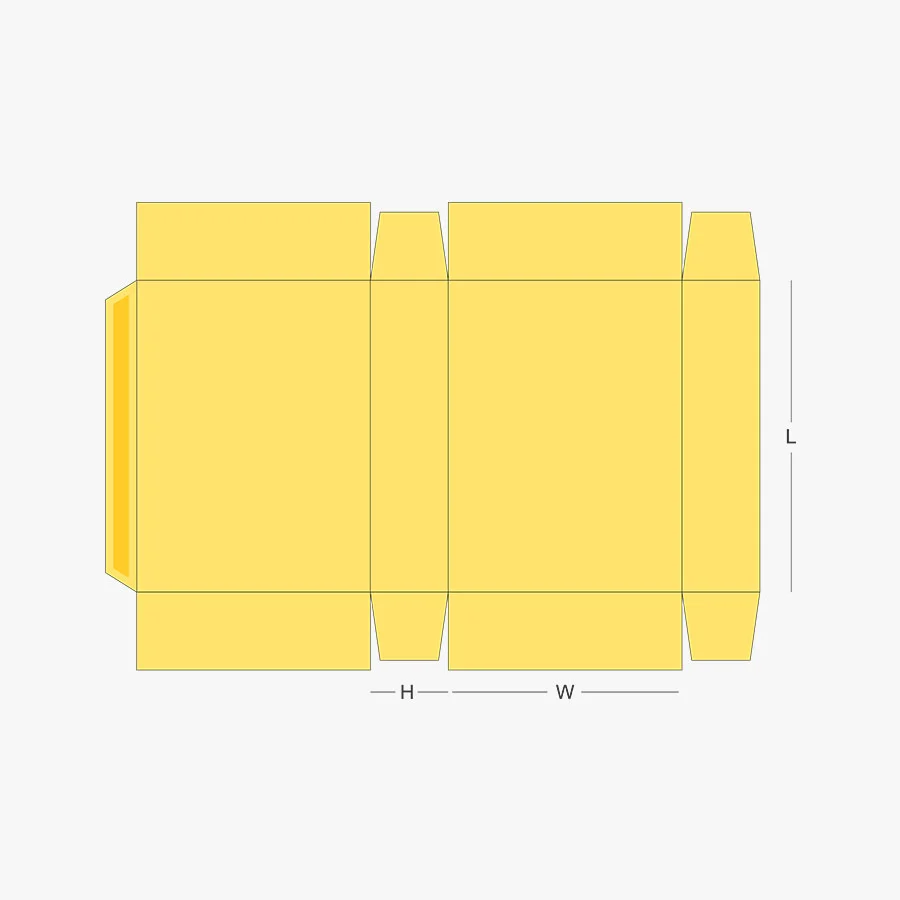

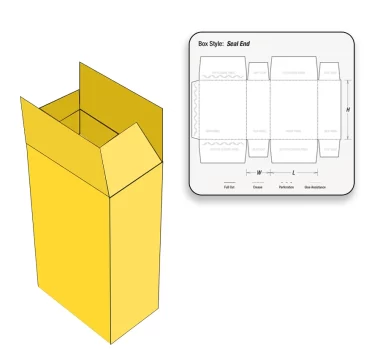

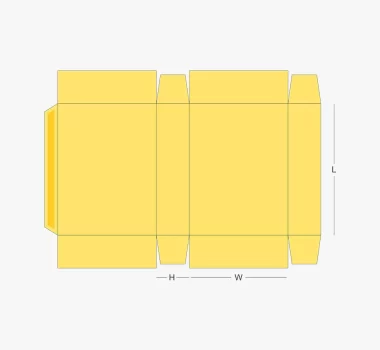

Searching for safe, durable, and easy-to-assemble packaging? Then, a seal-end box is the choice for you when you want to safely ship or store your products. These custom seal end boxes are designed with a tuck flap on one end and a seal closure on the other, which includes a degree of both convenience and protection. Seal-end custom packaging boxes can carry products for a variety of industries, including pharmaceuticals, cosmetics, food, and retail, keeping your products safe while maintaining a professional look. We sell seal-end custom boxes at wholesale prices, and we offer seal-end packaging boxes at eco-friendly materials, and a variety of seal end carton with full custom options, including premium materials, processes, and printing options.

Select from seal-end packaging boxes, seal-end cardboard boxes, or custom-printed seal-end boxes that are designed for structure and form. Order now to get affordable seal-end box packaging that not only locks your product with confidence but also promotes your brand.