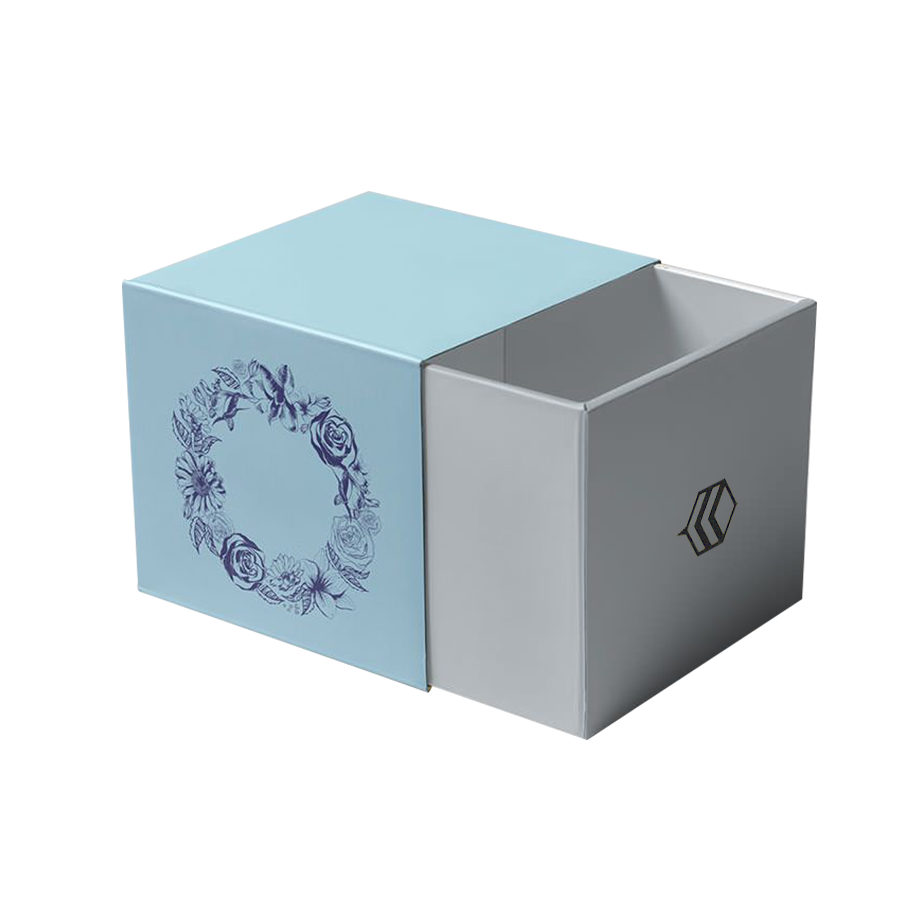

Are you in the market for the best sleeve boxes that not only secure your products through shipping and retail handling but also carry incredible customisations? If yes, you're at the right place. Packaging Bee manufactures the best custom sleeve boxes in the market that can help you transform your packaging into an effective branding and marketing tool.

We offer a vast array of packaging materials that help fulfil various packaging needs. Furthermore, our printing technique and colour models help you decorate the custom sleeve boxes with attractive prints. Using our add-ons and finishing coats, you can create packaging that can pull customers from afar. When designing the sleeve boxes, verify your designs using our prototyping options.

Get in touch with our customer care representatives, and let's make the best custom sleeve boxes in the market!