Get Premium Tuck End Boxes

Are you looking for safe and professional retail packaging? Our tuck end boxes are the perfect packaging solution for a multitude of products. Box packaging for retail products is perfect for every product location, whether you are selling cosmetics, electronics, food products, or fashion retail products. Tuck-end packaging will protect the item and ensure a professional presentation, and it can be set up without the use of adhesives.

At Packaging Bee UK, we offer custom tuck end boxes that we make from the finest packaging materials to your specifications for your brand. We can provide custom tuck boxes, straight tuck end boxes, tuck flap boxes, or seal end boxes. All are fully customisable, and we ship anywhere in the UK.

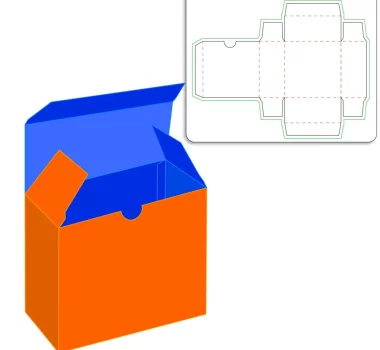

What is a Tuck-End Box?

Tuck end box packaging is a folding carton box that has a flap that tucks into the body of the box. The flaps can be on one or both ends, which makes for a quick and easy box to open, close, and secure. Tuck end custom box packaging has been used extensively for retail packaging due to its practical function and its polished appearance for retail presentation.

There are variances in tuck end boxes:

- Straight tuck end box: Flaps tuck in the same direction (top and bottom).

- Reverse tuck box: Top and bottom flaps tuck in opposite directions.

- Tuck flap box: A general style with tuckable end closures.

- Seal end boxes: Feature one end permanently sealed for added security.

What Basic Materials Can Be Used to Create a Tuck End Box?

There are multiple materials to utilise when creating tuck end boxes, depending on the product’s weight, texture, and also ultimately any desires that the brand has. The most popular materials include;

Cardstock

Lightweight material that is great for small retail items like cosmetics or perfumes.

Corrugated board

The best material to choose for items that need additional protection from the tuck end carton, especially if fragile or heavier.

Kraft paper

An eco-friendly and beautiful material to consider for natural, sustainable branding. It is best to attract eco-conscious buyers.

Rigid board

The ideal packaging material for luxury packaging or high-end goods. It adds premium protection to your product while guaranteeing ultimate security during and after shipping.

Many of these materials can be custom printed, die-cut, and coated in matte, gloss, or soft-touch finishes to take them to the next level.

What Are the Key Factors to Consider When Choosing the Right Material for a Tuck-End Box?

You can consider the following when selecting materials for your custom tuck end boxes:

Product Weight & Dimensions

Heavier products require thicker or corrugated boards. Lightweight products can typically be constructed with cardstock or kraft paper.

Protection Level

If your product is fragile, look for a material that resists bending and absorbs shocks.

Brand Image

A natural, eco brand may want to use Kraft tuck end packaging materials, while a luxury, high-end brand may want to use rigid materials with quality finishes.

Print Quality

If you require vibrant colours or fine detailing, use the smooth-finished coated stock for high-definition printing.

Budget

Some material options are lower in cost when produced in bulk, while you may want to use quality materials for a limited or luxury edition.

Where to Buy a Tuck-End Box?

You can purchase all styles of tuck-end boxes directly from us at Packaging Bee UK. Our specialisation lies in custom retail packaging with bespoke solutions for all businesses at a great price point.

Why Packaging Bee?

We can do everything in-house, including tuck-end boxes, expanding upon fully printed tuck-end packaging, with the backing of our UK team.

- UK-based – Quick turnaround and reliable delivery

- Custom Size & Printing – Made specific to your brand's specifications

- Low MOQ – Great options for start-ups or Limited Editions

- Eco-Friendly Options – Choose sustainable materials like kraft or recycled board

Explore Our Range of Tuck End Box Styles

We offer the following box styles for you, while you can request any other style you like or envision:

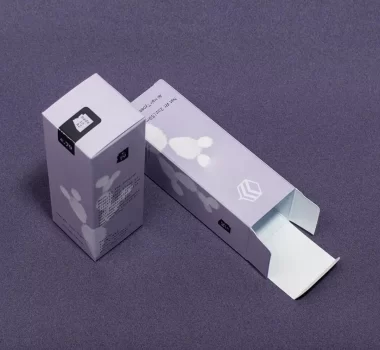

Straight Tuck End Box

The straight tuck end box has both flaps on the same side, giving it a clean front face that is easy to assemble. It is often used for beauty, supplements, and health items. The straight tuck end box features a seamless design, which helps with shelf appeal.

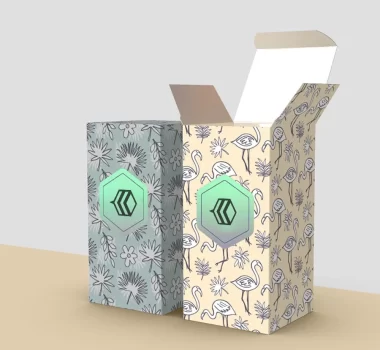

Reverse Tuck Box

In a reverse tuck box, the top and/or bottom flaps fold in opposite directions. Overall, this box style provides some balance and ease of closure. Reverse tuck boxes are usually found in electronics, medical items, and smaller retail packaging.

Tuck Flap Box

Tuck flap box is a broad term for any tuck-style box. Tuck flap boxes often appear in the food industry, small electronics, and toy products. Tuck flap boxes come in straight tuck and reverse tuck box styles.

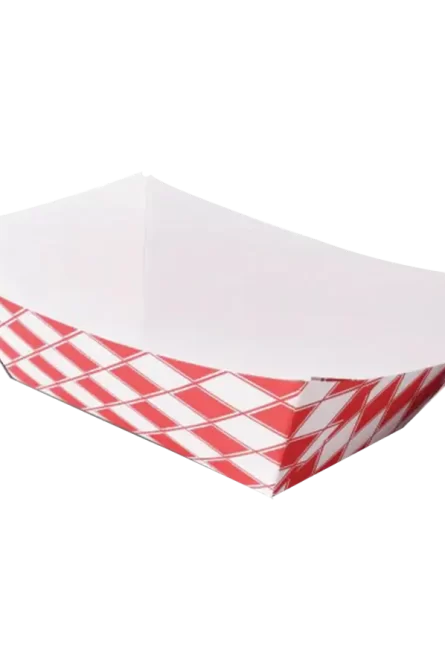

Seal End Boxes

Seal end boxes come with one end of the box sealed by adhesive and/or tape. Seal end boxes can provide enhanced security and tampering resistance. Seal end boxes can often be found in food packaging, pharmaceuticals, and subscription boxes.

Industries That Use Tuck End Packaging

We make the best boxes in town. Here are the benefits you will get if you collaborate with us for your packaging needs. Our tuck-end custom packaging is a hit in the following industries:

- Cosmetics & Skincare – Lip balms, creams, serums

- Food & Beverages – Snacks, tea, supplements

- Electronics – Chargers, cables, and gadgets

- Healthcare – Supplements, bandages, medical kits

- Retail & Gift Packaging – Small gifts, jewellery, candles

Ready to Place an Order?

Explore our extensive range of tuck-end packaging styles, or contact our team for a custom quote. We represent everything from small businesses to large retailers. At Packaging Bee UK, we provide custom tuck end boxes that protect your product while building your brand.

Order now and make your retail packaging smarter, easier, and stylish.