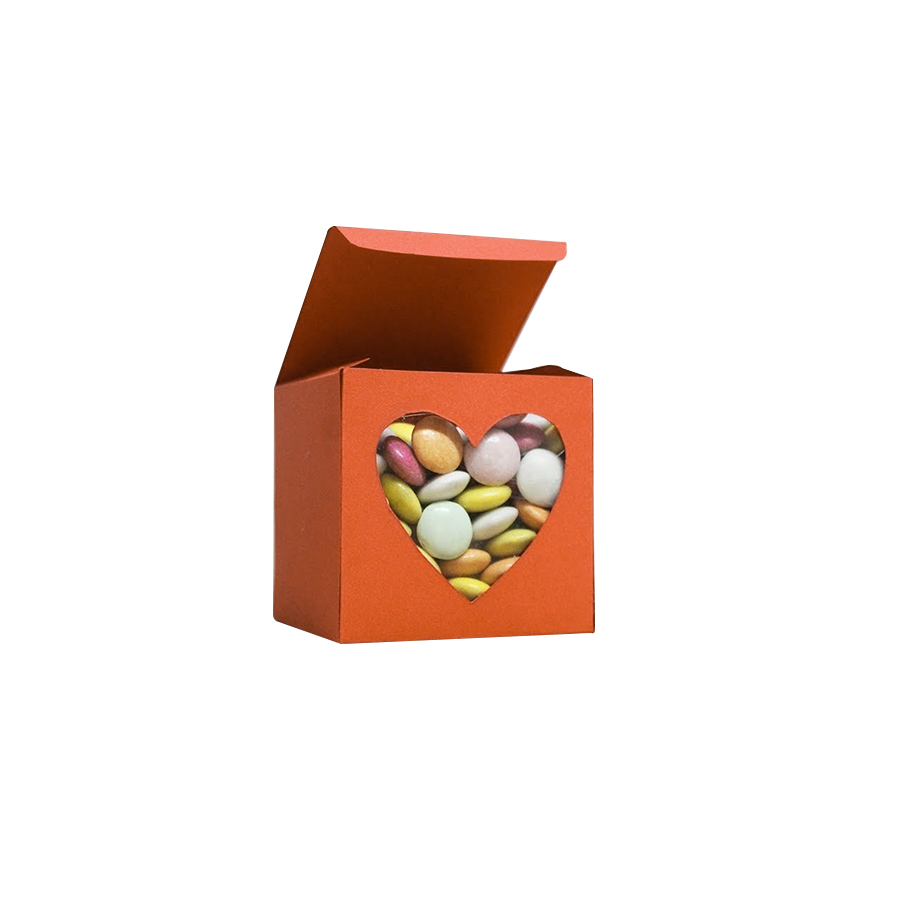

Are you looking for chocolate boxes that are as luxurious as the products you place in them? If yes, you're at the right place. Packaging Bee is one of the leading companies that create packaging solutions that can help take your business to the next level.

We offer high-class packaging materials that offer incredible protection through long-distance shipping and retail handling. Furthermore, we understand the importance of creating visually impressive chocolate gift boxes. We offer various printing techniques, colour models, add-ons, and finishing coats that help you out. Fix any design mistakes with our prototyping options.

Reach out today, and let's design chocolate boxes that make your customers come back for more!