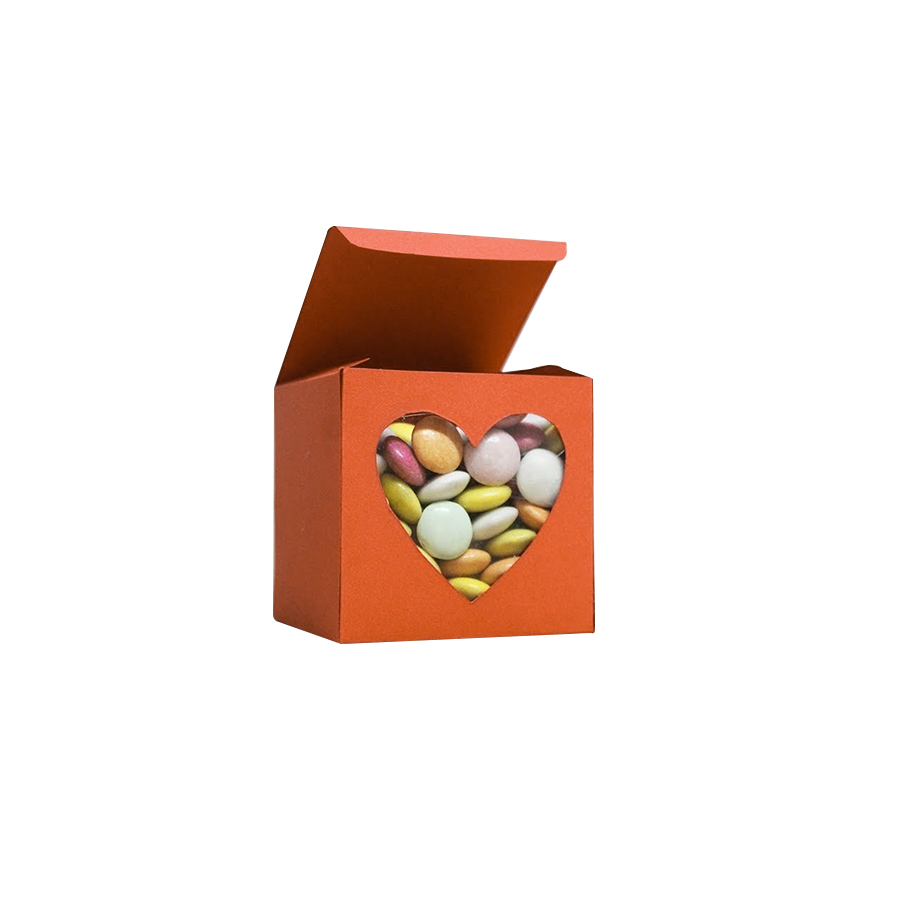

If you're in the market for pie boxes, look no further than The Packaging bee. We craft some of the best custom pie boxes in the market, and our customisation options are second to none. With high-quality packaging materials and a wide range of options to choose from, we can cater to all your packaging needs. So why settle for regular shapes and sizes when you can design your boxes to your heart's desire?

Our boxes are sturdy and stylish, making them ideal for both retail and gift-giving. Contact us today to learn more about our custom box options.