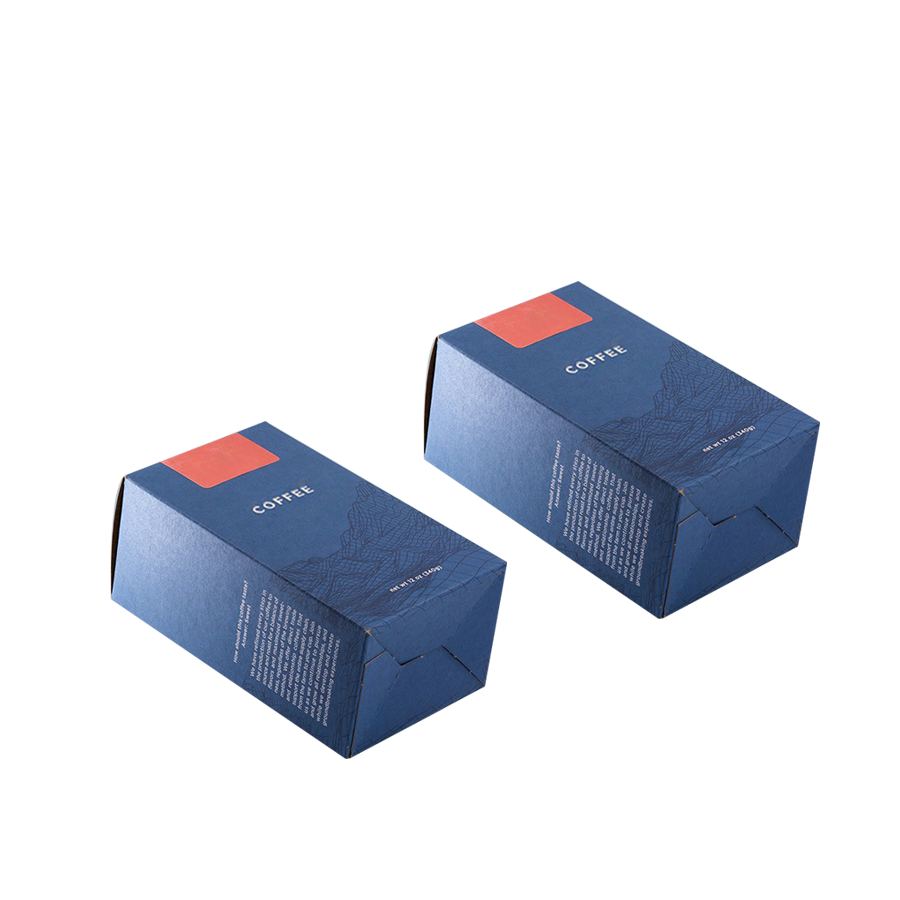

Are you looking for a packaging company that can craft the best coffee subscription boxes? If yes, then you've come to the right place. Packaging Bee is known for its expertise when it comes to coffee packaging. We can create coffee boxes for you based on your needs in custom shapes and sizes.

That's not all; Packaging Bee uses the latest printing technique along with different colour models to create the best possible coffee packaging. We also offer different packaging materials such as cardstock, cardboard, corrugated, rigid, and kraft material. So, whether you're looking for coffee bean packaging or coffee chocolate boxes, we've got your back. So, give us a call today and let's get started!